gravity liquid fillers

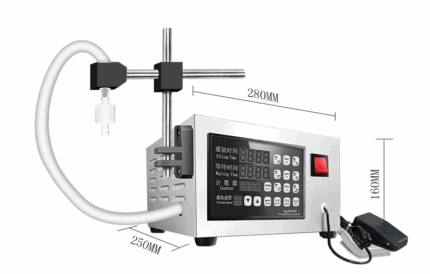

3.5L Double Digital Liquid Filler, Bottling Machine

Original price was: 682,37$.588,25$Current price is: 588,25$. Taxes included20L Digital Liquid Filling, Bottling and Dosing Machine

Original price was: 917,67$.823,55$Current price is: 823,55$. Taxes includedLiquid Dosing, Bottling, Filling Machine - Digital 2 ml - 3500 ml

Dosing machines, Liquid dosing machines, liquid fillers, bottle fillers, Filling Machines, gravity liquid fillers

Original price was: 411,78$.351,77$Current price is: 351,77$. Taxes included

Pneumatic dosing and bottling machine for dense and viscous products 50 ml

Dosing machines, Viscous dosing machines, liquid fillers, bottle fillers, Filling Machines, Fillers for dense and viscous liquids, gravity liquid fillers, Piston fillers, Chemical industry machines

Original price was: 529,43$.505,90$Current price is: 505,90$. Taxes included

⚖️ Gravity Fillers

The gravity fillers They are a simple, efficient and cost-effective solution for filling low viscosity liquids such as water, wine, vinegar, cleaning products, tonics, or pulp-free juices. They work by allowing the liquid to fall from a top reservoir into the container by the force of gravity, without the need for pumps or mechanical pressure.

🔹 Operating principle: The product flows naturally from the tank into the bottle when a dosing valve is opened. The flow is controlled by timers or level sensors, allowing the desired amount to be adjusted. Some models include anti-drip nozzles or float level control.

🔹 Advantages:

- Low cost and minimal maintenance

- Ideal for clear or non-foaming products

- Compatible with semi-automatic and automatic lines

- Simple and quick to clean structure

🔹 Limitations:

- Not recommended for dense or viscous products

- Not suitable for foamy liquids or liquids containing suspended solids

- Requires the tank to always be above the fill level

This technology is widely used in small and medium productions, in sectors such as Beverages, gourmet food, household cleaning products and light liquid cosmetics.

🔧 Other Related Technologies

🔹 Piston fillers – For viscous, foamy or pasty products.

🔹 Peristaltic fillers – High hygiene, ideal for cosmetics or pharmaceuticals.

🔹 Mass or magnetic flow fillers – Electronic precision for valuable liquids.

🔹 Vacuum fillers – For fragile containers, they ensure uniform level.

🔹 Rotary volumetric fillers – High speed on automatic lines.