Automatic cheese slicer

28.331,06$ Taxes included

INDUSTRIAL LABELLING MACHINE FOR 5 LITRE BOTTLES AND CARABS

17.184,74$ Taxes included

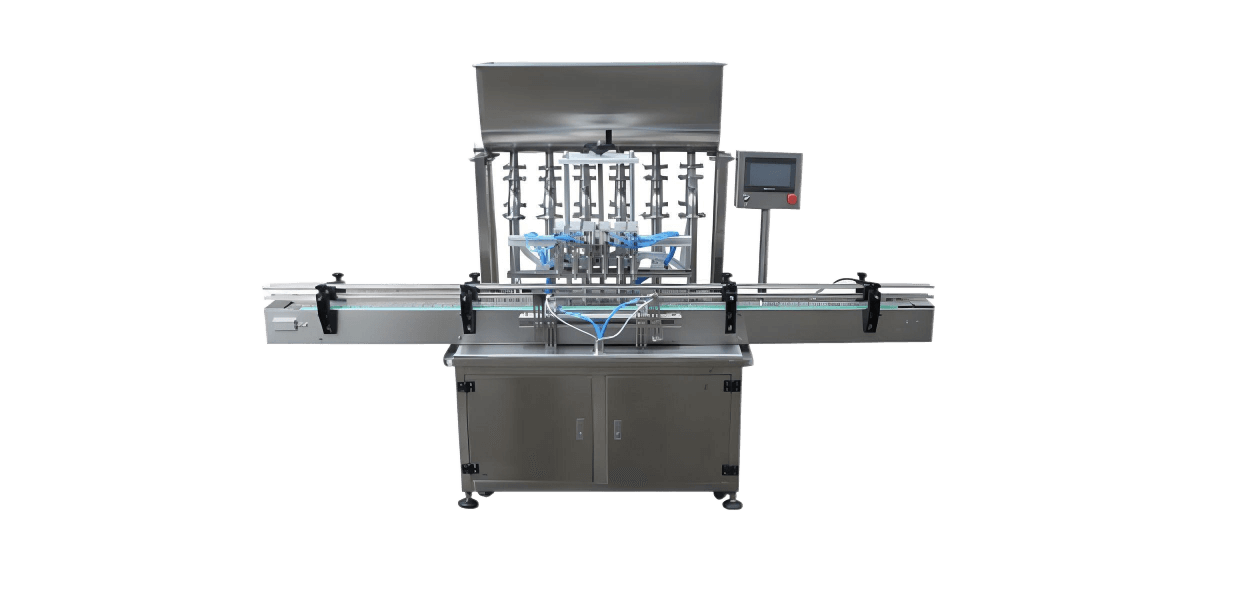

Linear bottling machine for viscous and foamy liquids

18.717,47$ Taxes included

video of complete linear bottling machine

SKU:

AR01321

Categories: Dosing machines, Liquid dosing machines, Viscous dosing machines, Piston fillers, Filling Machines

Description

🧴 Linear Bottling Machine for Viscous and Foamy Liquids – Up to 5 Liters with 4 Automatic Pistons

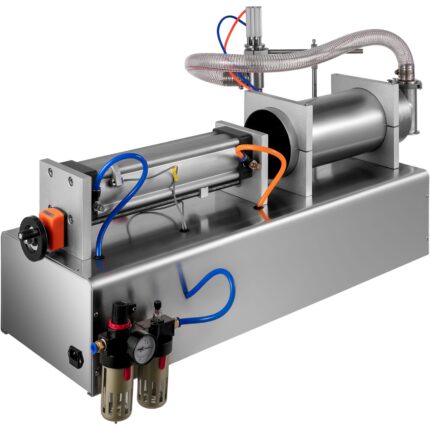

The linear bottling machine FF-AR5L4N has been designed to offer maximum versatility, precision and cleanliness for filling bottles and carafes of up to 5 liters. Its main advantage is that It can effectively handle both highly viscous products and foamy liquids., thanks to a nozzle system that gradually rise during filling, preventing the formation of foam.

This system is ideal for products such as Floor cleaners, detergents, gels, liquid soaps and other products that require gentle, controlled filling. In addition, the machine is equipped with four pistons of up to 5 liters each, allowing you to maintain high production speed without compromising accuracy.

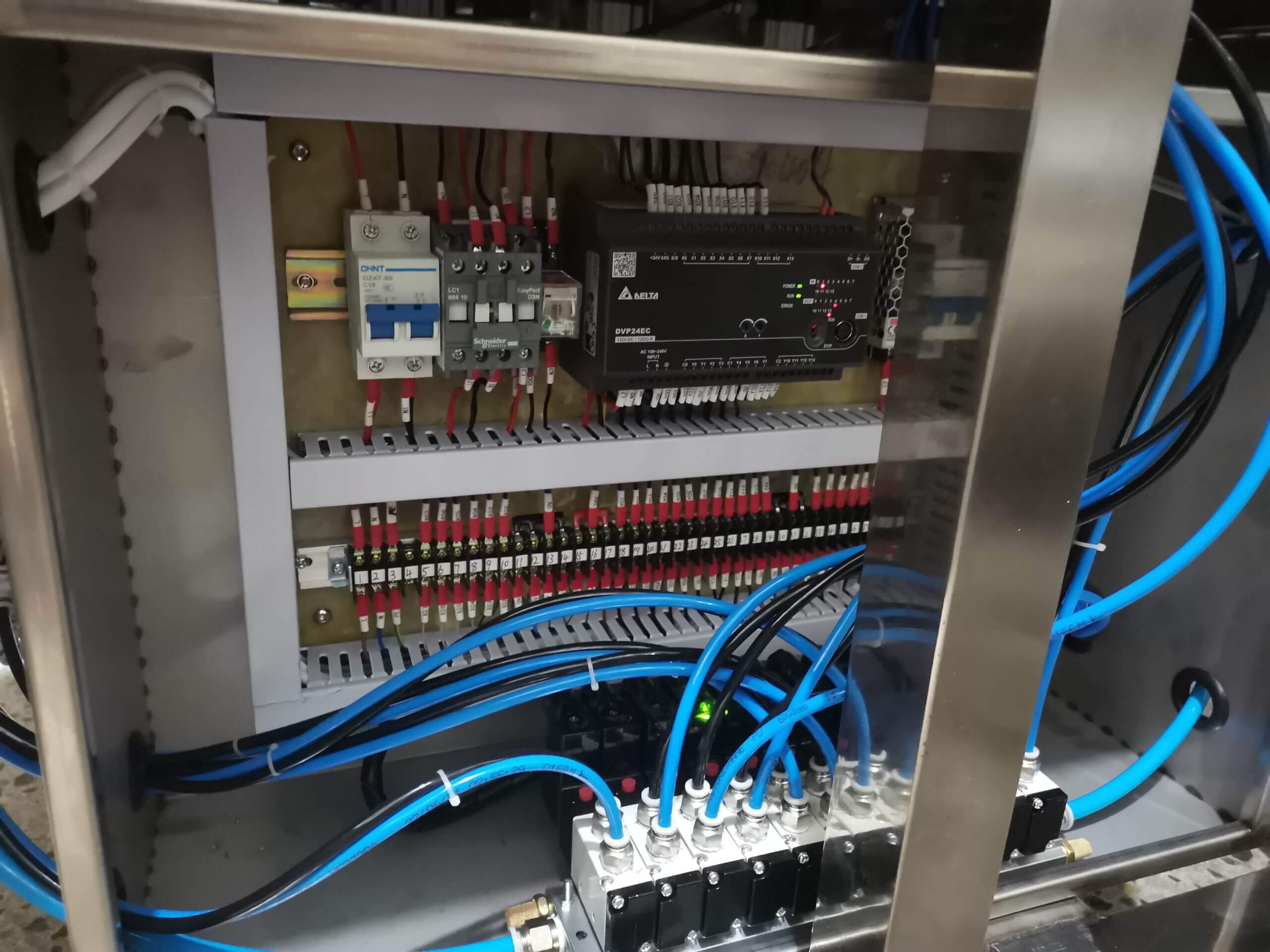

Filling is done from a intermediate tank automatically fed by a pump, which activates or stops depending on the tank level. This feature ensures a constant and stable supply of product, reducing downtime and improving overall line efficiency.

🧠 Transfer pump included

To facilitate work and improve system autonomy, The machine includes an automatic pump at no additional cost, which transfers the product directly from the main tanks (such as 1,000-liter IBCs or 200-liter drums) to the machine's intermediate tank. This pump activates automatically when the tank level drops and stops when it's full, ensuring a constant flow without manual intervention.

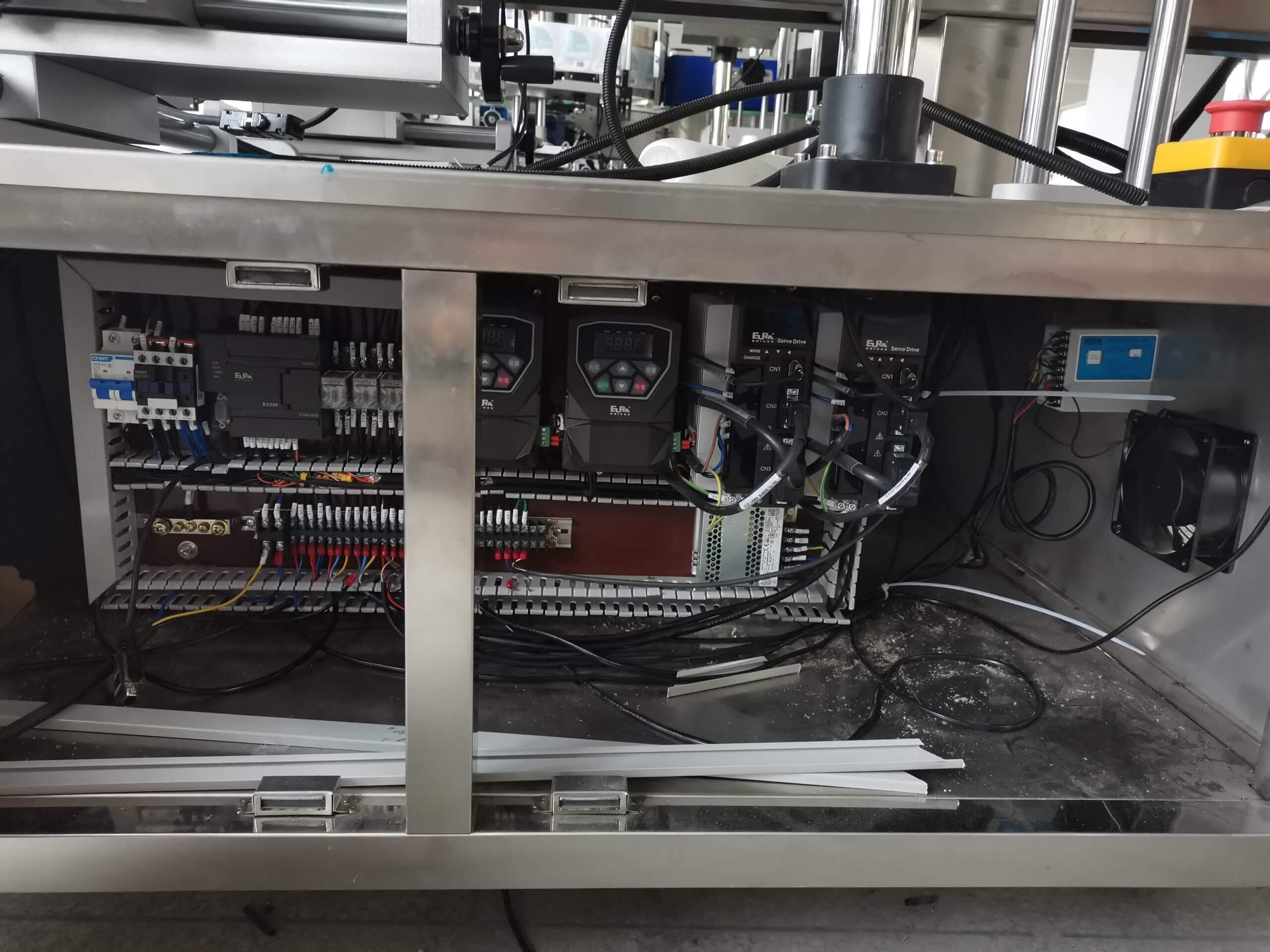

🌐 Multilingual and Smart Control Panel

The machine is equipped with a advanced digital control panel, from which the operator can manage all key functions of the filling process, including:

-

The speed and progress of the conveyor belt

-

The type of progressive lowering of the nozzles depending on the product

-

The opening and closing of the piston filling

-

The automatic system of activation of the drip tray after each cycle

This panel is available in 27 different languages, which allows ARC Distribution deliver each machine adapted to the client's native language. Although the default language is usually the English Being an industry standard, it offers the option of full customization based on the buyer's location, reinforcing ARC's commitment to international service and global ease of use.

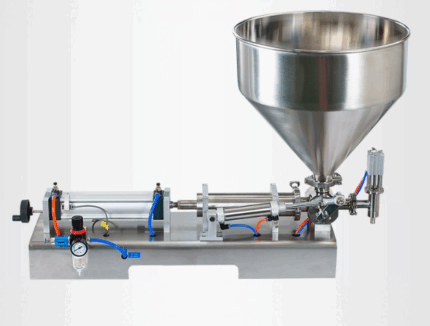

⚙️ Manual adjustment of the filling volume for greater precision

The only function that is not controlled from the front panel is the filling volume, as this is regulated manually from the rear of the machine. The system works with independent pistons, not with peristaltic pumps, which offers greater reliability and a more constant and powerful filling pressure.

For example:

-

If you want to fill 2-liter bottles, you simply need to adjust the piston position manually at the back.

-

If you then need to move on to 5-liter bottles, it will be enough mechanically modify the position of the piston stroke, without the need for electronic reprogramming.

This manual adjustment system guarantees a minimum error, a uniform pressure in each cycle and a long service life of the equipment. Although it is possible to integrate peristaltic pumps in some models for certain products, the system of pneumatic piston It remains the most robust and recommended option for most viscous and foamy liquids.

✅ Applications by industry

🧼 Cleaning and hygiene

-

Floor cleaner

-

Liquid detergent

-

Glass cleaner

-

Liquid soap for hands or body

-

Industrial degreasers

-

Floor polishes

-

Softeners

🧪 Chemicals and automotive

-

Coolants

-

Antifreeze

-

Engine cleaners

-

Windshield washer fluid

-

Alcohol or chlorine-based disinfectants

🍯 Food (particle-free)

-

Food syrups

-

Refined vegetable oils

-

Clear liquid vinegars and dressings

-

Liquid honey without crystallization

💄 Cosmetics and personal care

-

Shampoos and conditioners

-

Body gels

-

Liquid body creams

-

Moisturizing lotions

🧬 Pharmaceutical and laboratory

-

Dense pharmaceutical solutions

-

Particle-free oral serums

-

Disinfectants and hydroalcoholic gel

This machine can accurately fill containers of different sizes, from 1 litre bottles to 5 litre carafes, adapting automatically thanks to its adjustable conveyor belt and its guidance system. It also incorporates flow or weighing sensors, allowing for consistent dosing even with products of different densities.

In addition, it has systems integrated foam control, which automatically adjust speed or apply gentle vacuum to ensure bubble-free and spill-free filling.

Its robust structure, combined with high-quality components, makes it ideal for Industrial production lines seeking long-term reliability and efficiency.

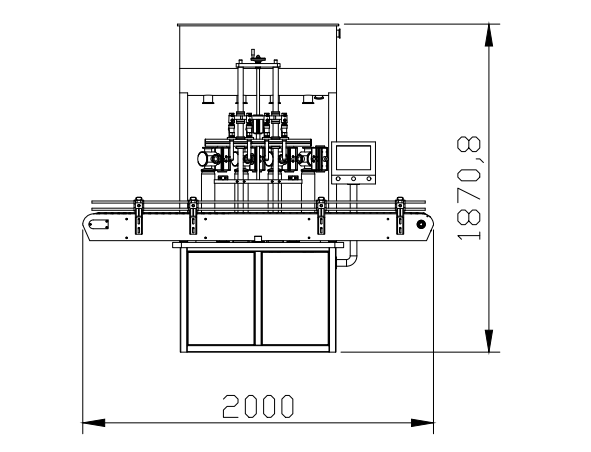

Technical Specifications

| Feature | Detail |

|---|---|

| Model name | Filling machine for foamy and viscous liquids |

| Code | FF-AR5L4N |

| Type of products | Viscous, foamy, and dense liquids without solids |

| Main applications | Cleaning, chemicals, cosmetics, pharmaceuticals, food |

| Filling range | 1 – 5 liters |

| Number of nozzles | 4 units |

| Filling system | Pneumatic piston + rising nozzles |

| Production speed | 15 – 20 bottles per minute |

| Power supply | AC 110V 60Hz / 220V 50Hz |

| Air supply | 0.4 – 0.9 MPa |

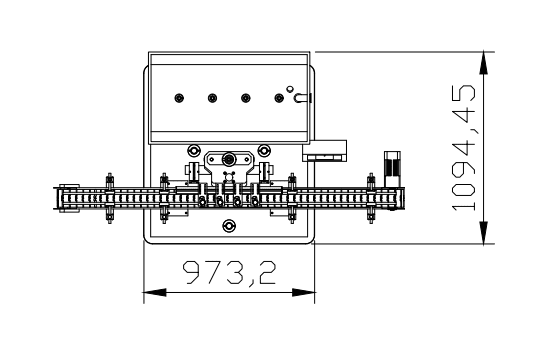

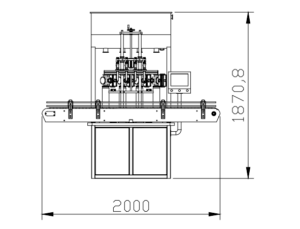

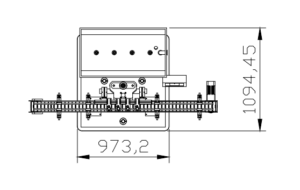

| Machine measurement | 200cm (L) × 110cm (W) × 187cm (H) |

| Net weight | 420 kg |

| Tank system | Automatic feeding with pump and level control |

| Foam control | Adjustable speed and gentle vacuum |

| Type of compatible packaging | Plastic or glass bottles and carafes (1 to 5 L) |

| Certification | EC |

| Mode of operation | Automatic with conveyor belt |

| Material in contact | Food grade stainless steel |

| Technical support | Including |

| Warranty | 2 years |

Automatic configuration of the filling machine

Reviews (0)

Only logged in customers who have purchased this product may leave a review.

You may also like…

Packing Machine, Packaging Machine, Bag Filler, Dosing Machine for Powder, Lentils and Legumes?

Dosing, Bottling, Filling and Packaging Machine 100 ml - 1000 ml

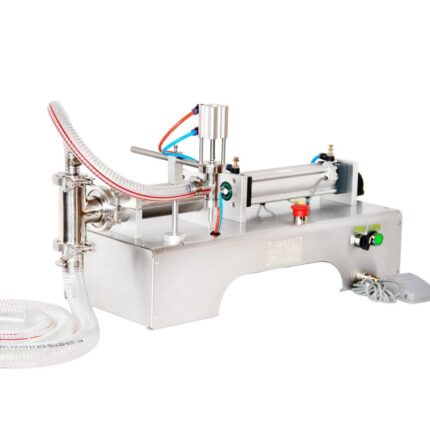

Pneumatic dosing and bottling machine for dense and viscous products 50 ml

Dosing machines, Viscous dosing machines, liquid fillers, bottle fillers, Filling Machines, Fillers for dense and viscous liquids, gravity liquid fillers, Piston fillers, Chemical industry machines

Pneumatic Piston Liquid Filler by Suction Bottling, Dosing 1000 ml?

Rated 5.00 out of 5

1.778,10$ Taxes included

Related products

Centrifugal pump for feeding

Bottling machine for water, liquids, bleach, reagents, juice 1000-5000ml

Bottling machine for viscous liquids, oil, detergent, 500 to 5000ml

Dosing, bottling, with mixer and double filler 100 ml - 1000 ml

Dosing, Bottling, Filling Machine with Whisk 50 ml - 500 ml

Packing Machine, Packaging Machine, Bag Filler, Dosing Machine for Powder, Lentils, Legumes?

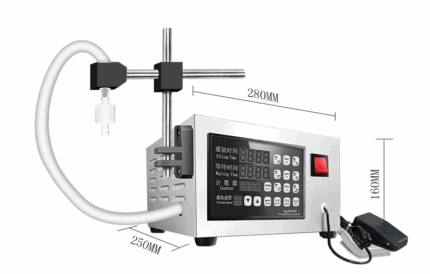

Liquid Dosing, Bottling, Filling Machine - Digital 2 ml - 3500 ml

Dosing machines, Liquid dosing machines, liquid fillers, bottle fillers, Filling Machines, gravity liquid fillers

Reviews

There are no reviews yet.